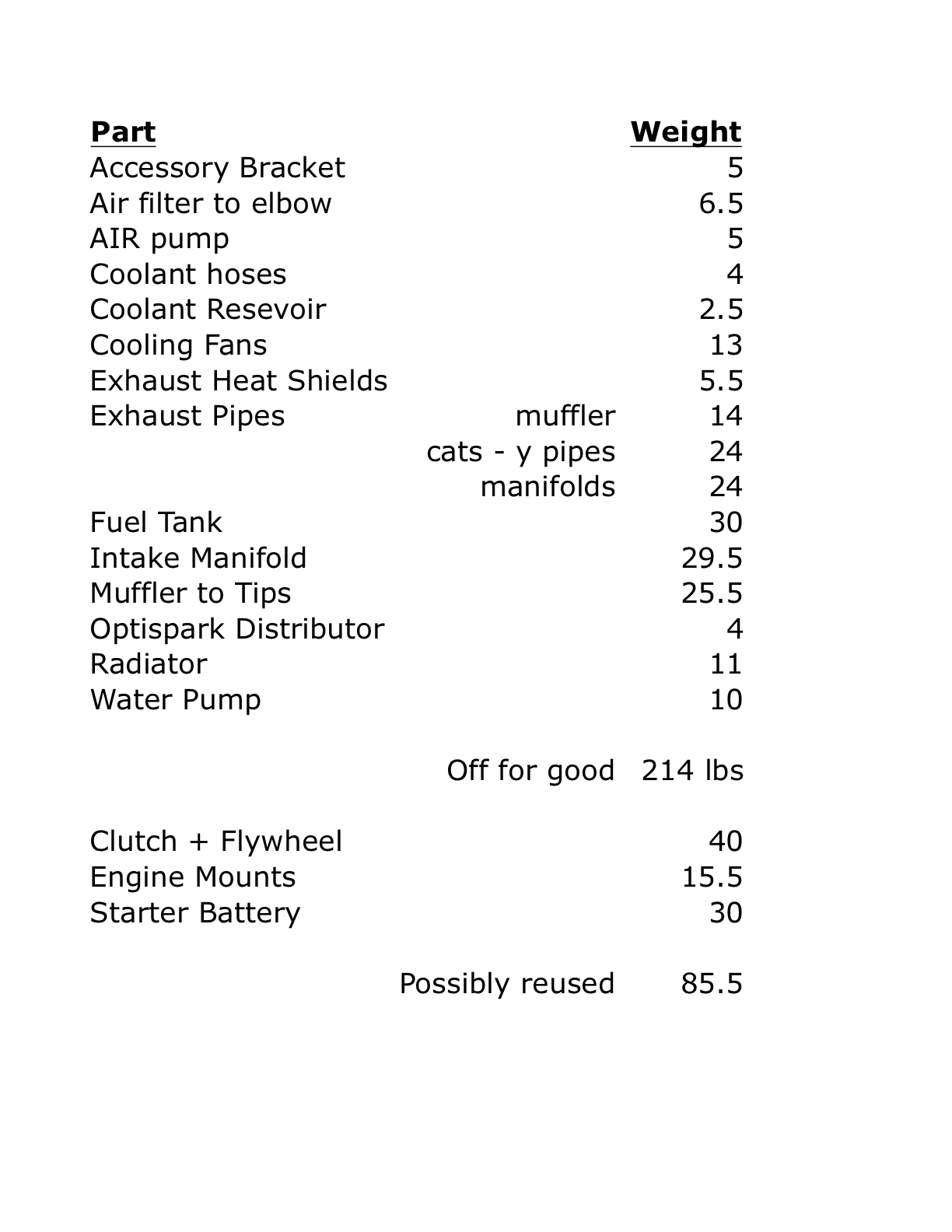

Adapter ideas

Sunday, November 30th, 2008Lately I’ve been doing a lot of visualization of how the motor and transmission will couple. I plan to keep the clutch and transmission so I’ll need an adapter to mate the flywheel to the motor. Electro Automotive’s site was very helpful to me in understanding how the pieces fit together. The taperlock bushing was a new concept to me. I know how the pieces will fit together, but don’t have a solid idea of the depth of the adapters – that will determine the distance from the flywheel face to the rear of the motor.

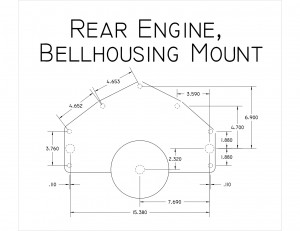

I found a drawing that is the layout of the rear of my engine, front of the bellhousing. This is extremely helpful because I’d previously matched up the bolt holes to holes I made in a used pizza box.

This is a drawing of the type of adapter I’ll need. The dimensions are just working numbers to help me understand how the gap closes. I’ll leave it to the machine shop to determine the actual bushing dimensions.

[I removed the image because it wasn’t accurate and don’t want to confuse anybody]