Task List

Saturday, April 24th, 2010This is intended to be a list of everything I can think of that is left in Version 2.0. I’ll cross things off as they’re complete and add on as I figure out more stuff I forgot. Not too much further, although there is obviously stuff I’m missing.

Low Voltage

- Wiring for + and – LV to terminal bus

- Wiring from relocated negative contactor Raptor negative to DC/DC

- Vacuum relay triggers to terminal bus in control box.

- Split loom on wiring – What a pain, delayed

- Connectors for positive and negative from DC/DC to battery

- Raptor sensor wiring

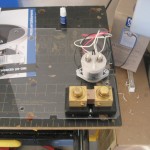

Manual Disconnect

- Bike brake cable from cabin to breaker

- Handle for brake cable

Throttle

- Test the pot box for full throttle

- Secure cable to frame

- Reattach the return spring securely

High Voltage Cables

- Purchase bolts for negative contactor and motor

- Cable from control box to Raptor B+

- Reconnect all battery strings (front batteries) (rear batteries) (front to back)

- Connect charging cable to most positive

- Connect charging cable to most negative

- Mount negative contactor and wire to switch and ground.

High Voltage Conduit System

- Determine cable routing

- Locate bracket points

- Determine split for negative to enter contactor box

Battery Regulators

- Phone cable from front to back

- Phone cable to charger

- Test with yellow light

- Troubleshoot front regulator erratic behavior

Miscellaneous

- Secure the ABS sensor on top of the rear axle

- Check air pressure in suspension bags

- Top off battery charge

- Tee fitting for vacuum line to operate A/C valves

- Alignment for manual steering rack